What types of Stencil Materials do we sell?

-

Mylar Stencil Material:

- We have 4 grades of mylar which is the most popular choice for stencils

- Our 4 mil mylar is great for Cricut and Silhouette Cutters.

- 7.5 mil mylar which is a great performer

- 10 mil mylar which is the most popular grade for our customers

- Super tough 14 mil for outdoor and for where you want to achieve build on the stencil.

-

Oil Board Stencil Material

- This traditional material is eco-friendly made of paper and natural oils.

-

Adhesive Backed Materials

- This mylar material is pre-set up with adhesive to make it easier to stencil. Good for automotive painting.

-

Contractor Materials: LLDPE, LDPE, and HDPE

- These thicker materials are best for spray only and are designed for outside use.

What Material is used to make Stencils?

Many materials have been used for stencils. paper, wood, metal and a range of plastics and all can work to a degree. For our customers, we believe that Mylar is the best material for interior use and for use on vertical surfaces and we like LLDPE for use outdoors on pavement, concrete, and grass.

What makes a good stencil material?

- You must be able to cut it. Stencils are simply materials with holes in them and you have to be able to cut them. If you are using a knife that will limit what materials will work well. so you will want to stick to paper and perhaps thin plastics. The downside of stencils that are easy to cut is that they also are easier to tear. So these stencils are good for usually just a few uses.

- You do not want them to stretch? Stencils are used to replicate images or letters. if the image stretches as you are using it you will not get a good result. This is the main reason why we avoid vinyl as while they are inexpensive they will easily stretch and not replicate the image consistently.

- The materials must be able to withstand the paint or ink that you are using. This is the downside of paper stencils as they will absorb and get saturated by the paint or ink which reduces their longevity,

- Stencils should be tough and able to withstand both painting and even better cleaning so that they can be sued many times.

- Stencils are best if they are flexible so that they can conform to rounded surfaces,

- Finally, the best stencils are thin so that paint can be applied with a brush, roller, or spray. We find stencils of 1/16th of an inch thick or more are difficult to use with a roller and are best used with a spray application.

What is the best material for stencils?

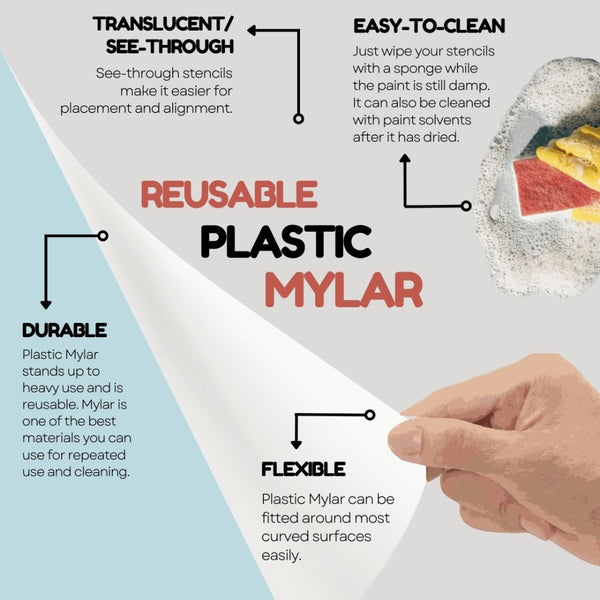

- Mylar is the best material for stencils for the majority of uses. It has a combination of properties that make it perfect for most stenciling jobs. It is thin, light, and flexible but also very strong and durable. You can use mylar stencils many times and it is cleanable. Thin allows you to apply paint with brush and roller and keep you from creating a paint lip at the edge. Light makes it easy to use on vertical surfaces like walls. Mylar comes in many different thicknesses.

- Mylar is not the best for Outdoor applications of large stencils like parking lots and sports fields, thicker material lie 1/16th inch or 1/8th inch thick LLDPE is the preferred material. This material is best used with spray applicators and is designed to be used hundreds of times by professionals

- Adhesive-backed polypropylene is preferred by professionals in auto and industrial paint shops as well as for Tattoo stencils. These are all spray and airbrush applications on curved surfaces so that the adhesive is very helpful.

- For the Environmentally conscious there is traditional oil board with paper impregnated with plant oils so that it does not absorb paint.

- Magnetic film is a very popular niche product that is great for marking metal equipment, tools, and structures

Why is mylar a great stencil material?

- This is extremely tough and hard-to-rip material. It can be used many times.

- It is flexible so that it can be rolled and will conform to curved surfaces.

- It is dimensionally stable so that it does not stretch and will keep its shape

- It is translucent so that you can see contrast through it allowing perfect placement for stencils.

- Paint does not like to stick to it so it is easy to clean. And can be used more times.

- It cuts fairly easily. 4 mil is easy to cut with the Gyro-Cut, Cricut, and Silhouette cutters, 7 mil can be cut with the Gyro-Cut Pro and with the heavier-duty cutters. 10 and 14 mil to cut your own a heated stencil cutting tool or a laser cutter is the best way.

Mylar Properties: All grades of mylar are:

- Translucent material, you can see contrast through, it so it is easy to place in the correct spot.

- Food grade material.

- Very durable yet flexible. Dimensionally stable and do not stretch like vinyl

- The only difference is in the thickness of the mylar. A mil is 1/1000th of an inch. Newspaper is approximately 3 mil, a business card is about 12 mil. We offer 4, 7.5, 10 and 14 mil. As you get thicker the mylar is stiffer and will be slightly more opaque.

Which Mylar is best for cutting stencils?:

- All of our mylars make great stencils. The major difference is in how they will be cut.

- For manual knife cutting we recommend 4 mil mylar. It cuts easily with a scalpel like knife though we recommend our Gyro cutter. This tool is easy to learn and can easily cut straight lines and curves. It is perfect for tracing a printed picture.

- For consumer grade electric cutters like the Cricut and Silhouette 4 mil Mylar is the best stencil material. 4 mil will cut consistently, the thicker materials will not.

- 7 mil mylar can be cut with a gyro cutter with significant pressure. 10 mil and 14 mil cannot be done.

- A heated cutter like a Wall lenk is the only manual cutting tool for 10 mil and 14 mil mylar.

- Heavy duty industrial grade cutters like the Cricut Maker can cut 7 and 10 mil mylar.

Tips for creating your own stencils:

1. Use the correct surface. when using a manual knife or Gyro cutter protect your table, I like using a self-healing mat or you can use a cutting board from the kitchen. A cutting board also works for the heated cutter though you will likely get some plastic residue on the cutting surface so don't use your favorite kitchen board...I learned the hard way.

2. Tape or use our Repositionable Spray Adhesive to hold the stencil to keep it from moving during the cutting. If you are tracing a picture or printed lettering fix that first to the cutting surface and fix the stencil material over the picture.

3. Slowly and methodically cut the stencil along your pattern. You can lift up to insure that you have cut corners completely.

Why Mylar is the best material for stenciling?

Stenciling is a traditional yet still highly effective method for rendering lettering, graphics and artwork on surfaces. It allows those of us without the ability to draw to make professional and pleasing displays.

So the stencil material:

1. Must have openings cut precisely into it with available tools.

2. Must maintain those openings' spatial relationships from the time it is cut until it is used.

3. Must not be impacted by the paint or material used to project the art.

4. Must be able to be cleaned or be a few use stencil.

5. Finally, unless the stencil is being cut with a computer-controlled machine, it needs to be transparent enough so that one can see contrast through it.

Paper stencils are problematic: The simplest and most common material is paper. While usable paper has some fatal flaws. While easy to cut, it is even easier to tear. While OK for large lettering, fine stencilling is not possible as the smaller breaks will tear. It if is not kept flat or rolled carefully it will fold or crinkle and lose its spatial integrity ( the art will not be in correct place.) It is hard to trace as it is generally too opaque. Unless it is coated it will absorb paint. Finally it is not cleanable.

Be wary of vinyl. People also try to use vinyl. It is easy to cut, and it does stand up to paint. But it can stretch and tear fairly easily. Take great care when placing these stencils.

We recommend mylar. If you are cutting by hand or using an electric cutter 4 mil is easy to cut, it does not stretch or crinkle with reasonable care. It is still quite tough and can handle fairly fine detail. It is fairly transparent making it easy to trace cut from a drawing or a picture. It can handle most paints and can even be carefully cleaned. 4 mil also can be molded around curved surfaces which is very handy.

The thicker grades of mylar 7, 10 and 14 mil increase in durability, but are tougher to cut. These require either a hot knife, a commercial-grade cutter, or a laser cutter. They also become milkier is they are thicker and 14 mil is difficult to trace cut. The also become somewhat stiffer. We do not recommend 14 mil for rounded surfaces. However, these stencils can be cleaned and with proper care can last for hundreds of uses.

>